Strong Weatherability

The Veenice Polyimide in the high (low) temperature environment can maintain good tensile and impact strength properties, good heat resistance and weatherability, Machine washable, resistant to most organic solvents; anti-UV, protection coefficient is up to 50.

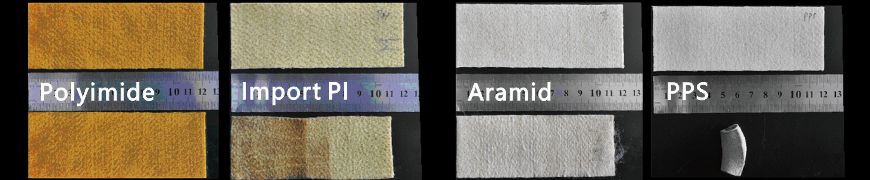

Our test:

| Water vapor contraction in 24 hours | Sample size before treatment warp(cm) , zonal(cm) |

Sample size after treatment warp(cm) , zonal(cm) |

Contraction coefficient (%) |

| Polyimide non-woven fabrics | 4.5 , 12 | 4.49 , 11.98 | 0.39 |

| Import PI non-woven | 4.5 ,12 | 4.22 , 11.1 | 13.32 |

| Aramid non-woven fabrics | 4.5 , 12 | 4.28 , 11.15 | 11.56 |

| PPS non-woven fabrics | 4.5 , 12 | contracted and stiffened | - |

| Polyimide staple fiber | 50.56 | 50.38 | 0.36 |

| Import PI staple fiber | 60 | 53.1 | 11.5 |

| Aramid staple fiber | 48.42 | 46 | 5 |

| PPS staple fiber | 60 | contracted and agglomerated | - |

Water vapor at 160-185 ℃ after 24 hours :